Finding the sweet spot is key when it comes to the tightness of clamps on a tonneau cover.

You want them snug enough to hold the cover securely in place but not so tight that they cause damage.

Today we will answer how tight should clamps be on a tonneau cover and also give you step by step guideline.

How Tight Should Clamps Be On A Tonneau Cover?

The tightness of the clamps on a tonneau cover will vary depending on the type of cover and the make and model of your truck.

However, the clamps should generally be tightened until they are snug but not too tight.

If the clamps are too tight, they could damage the cover or the truck bed. If the clamps are too loose, the cover could come loose while driving, which could be dangerous.

Signs of Over- or Under-Tightening Clamps Of tonneau Cover

Look for Visible Gaps

Examine the area where the tonneau cover meets the truck bed rails.

A clear indication of under-tightening is the presence of visible gaps between the cover and the bed rails.

If you notice any noticeable spaces or irregularities, it suggests that the clamps are not securing the cover tightly enough.

Check for Excessive Movement

Gently shake the tonneau cover from side to side and observe how much it moves.

If the cover wiggles excessively or feels loose, it is likely a sign of under-tightening.

The clamps should hold the cover firmly in place, minimizing any significant movement.

Inspect for Deformation or Bending

Pay close attention to the tonneau cover clamps themselves. Look for any signs of deformation, bending, or warping.

Over-tightening the clamps can place excessive stress on them, leading to physical damage.

If you notice any irregularities or changes in the shape of the clamps, it may indicate over-tightening.

Assess the Rubber Seals

Inspect the rubber seals that run along the edges of the tonneau cover. Over-tightening the clamps can cause the seals to compress, resulting in deformation or gaps.

Conversely, under-tightening can leave gaps that compromise the cover’s weatherproofing capabilities.

Ensure the rubber seals maintain their shape. Create a proper seal without excessive compression or separation.

Observe Water Accumulation

After rain or washing your vehicle, check the tonneau cover for water buildup.

Tightened clamps can distort the cover, causing misalignment with the bed rails and allowing water to enter.

Over-tightened clamps create gaps, while under-tightened ones lead to pooling. If water seeps in or pools excessively, it indicates a problem with the clamps.

Evaluate Security

Consider the overall security of the tonneau cover. An over-tightened clamp can strain the cover and weaken its ability to resist tampering or potential theft attempts.

An under-tightened clamp may allow unauthorized access or compromise the cover’s locking mechanism.

Ensure the clamps are tightened adequately to maintain the cover’s security features.

Step-by-Step Guide: How to Properly Tighten Clamps on a Tonneau Cover

Step 1: Gather the Necessary Tools

You’ll need a few essential tools to tighten clamps on a tonneau cover properly.

Ensure you have a socket wrench with the appropriate size to fit the clamps on your tonneau cover.

Grab a measuring tape or ruler to ensure consistent tightening across all clamps. Having these tools handy will make the process smoother and more efficient.

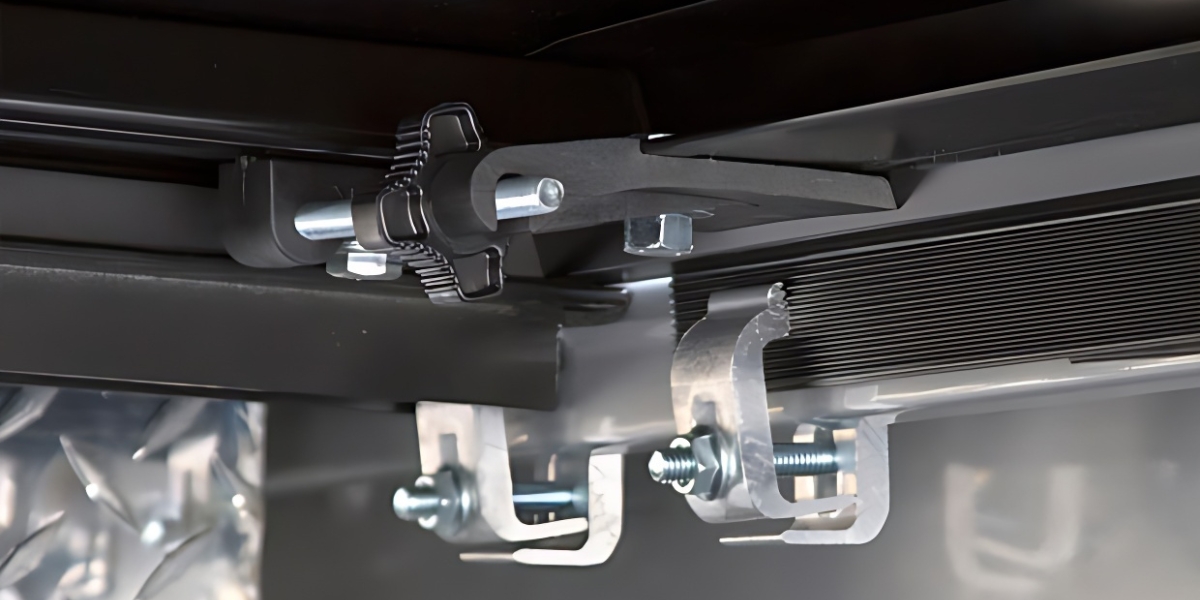

Step 2: Identify the Clamp Type

Tonneau covers come with different clamp designs, so it’s crucial to identify the specific type you’re working with.

The two most common clamp types are C-clamps and J-hooks. C-clamps have a straightforward design with a screw-like mechanism, while J-hooks resemble the letter “J” and latch onto the truck bedrail.

Understanding the clamp type will help you apply the appropriate tightening technique.

Step 3: Position the Tonneau Cover Properly

Before tightening the clamps, ensure that the tonneau cover is correctly positioned on your truck bed.

Align it according to the manufacturer’s instructions, ensuring that it fits snugly and evenly.

Proper alignment will facilitate clamping and ensure a secure and weather-resistant seal.

Step 4: Loosen the Clamps

Begin by loosening all the clamps on your tonneau cover. Use the socket wrench to turn the screws counterclockwise or release the J-hooks’ tension.

Loosening the clamps allows you to reposition them and ensure a consistent tightening procedure.

Step 5: Tighten the Clamps Gradually

Now it’s time to tighten the clamps to secure your tonneau cover effectively. Start with one clamp at a time, applying gradual pressure to avoid overtightening.

Turn the screw clockwise using the socket wrench for C-clamps until the clamp feels secure.

If you’re working with J-hooks, tighten them by pulling the hook down until it latches firmly onto the truck bedrail.

Step 6: Maintain Equal Tightness

As you tighten each clamp, pay close attention to maintain equal tightness across all clamps.

To achieve this, use the measuring tape or ruler to measure the distance between the tonneau cover and the truck bedrail at each clamp location.

Adjust the tightness of each clamp accordingly until the measurements are consistent. This ensures a balanced and secure fit for your tonneau cover.

Step 7: Double-Check and Test

Once all clamps are tightened, and the measurements are consistent, give your tonneau cover a final inspection.

Ensure all clamps are securely fastened, and the cover sits snugly on the truck bed.

Take a moment to test the tonneau cover by gently pressing on different areas to check for any signs of movement or looseness.

Factors To Consider When Tightening Clamps Of The Tonneau Cover

Assess the Material

Before tightening the clamps, consider the material of your tonneau cover. Different tonneau covers are made of various materials, such as vinyl, aluminum, or fiberglass.

Each material has its own specific requirements for tightening. For example, vinyl covers may require slightly less tension to prevent damage, while aluminum covers may need a firmer grip.

Identify the Clamp Type

Different types of clamps are used for tonneau covers, such as C-clamps, rotary clamps, or latch clamps.

Each type has its own tightening mechanism and specifications. Familiarize yourself with the specific type of clamps used on your tonneau cover and understand how they function.

This knowledge will help you properly tighten the clamps and avoid potential damage.

Determine the Tightening Method

Depending on the tonneau cover design, you may need to use a specific tightening method.

Some covers require turning a bolt or knob, while others may have a latch or lever mechanism.

Be cautious not to overtighten or under-tighten, as both can lead to issues with the cover’s performance.

Apply Even Pressure

When tightening the clamps, applying even pressure across all clamps is crucial. Uneven tightening can cause the cover to sit unevenly, resulting in gaps or leaks.

Start by lightly tightening each clamp, then gradually increase the tension in a balanced manner.

Check the alignment and fit of the tonneau regularly covered while tightening it to ensure proper symmetry.

Avoid Excessive Force

While securing the tonneau cover tightly is important, be cautious not to apply excessive force when tightening the clamps.

Over-tightening can lead to deformations, cracks, or other damage to the cover or clamps.

Remember that the goal is to achieve a snug, secure fit without straining the components.

Regularly Inspect and Adjust

After initially tightening the clamps, regularly inspect the tonneau cover for any signs of loosening, gaps, or misalignment.

Factors like temperature changes, vehicle vibrations, or usage can affect the tightness of the clamps over time.

Make it a habit to periodically check and adjust the clamps as needed to maintain optimal performance.

The Impact of Proper Clamp Tightness on Tonneau Cover Performance

Secure Cargo Protection

Proper clamp tightness ensures a tight seal between the tonneau cover and your truck bed.

This seal prevents water, dust, dirt, and other elements from infiltrating your truck bed and damaging your cargo.

Maintaining the right clamp tightness creates a barrier that safeguards your belongings from external hazards.

Enhanced Aerodynamics

A tightly secured tonneau cover reduces wind resistance as you drive, improving aerodynamics.

The smooth airflow over your truck bed reduces drag, which can enhance fuel efficiency.

Proper clamp tightness allows you to experience better gas mileage, making your journeys more cost-effective.

Prevention of Flapping and Vibrations

Insufficient clamp tightness can lead to flapping and vibrations of the tonneau cover while driving at high speeds.

These disturbances cause annoying noise and strain the tonneau cover material and its attachment points.

Properly tightened clamps keep the cover taut, minimizing flapping and vibrations for a quieter and more enjoyable ride.

Protection Against Theft

Maintaining optimal clamp tightness bolsters the security of your truck bed and its contents. A locked tonneau cover prevents burglars from taking your things.

By ensuring that the clamps are tightly fastened, you fortify the defense against unauthorized entry.

Durability and Longevity

Proper clamp tightness plays a vital role in preserving the longevity and durability of your tonneau cover.

When the clamps are securely fastened, they distribute the tension evenly, minimizing stress on the cover material and its components.

This balanced tension reduces the risk of tears, cracks, or damage, allowing your tonneau cover to withstand the test of time.

Minimized Wear and Tear

Insufficient clamp tightness can result in excessive movement of the tonneau cover, causing wear and tear on the cover material and its attachments.

Over time, this can lead to loose screws, damaged clamps, and compromised performance.

By regularly checking and adjusting the clamp tightness, you can mitigate unnecessary wear and tear, prolonging the lifespan of your tonneau cover.

Peace of Mind

Maintaining proper clamp tightness offers peace of mind while driving and leaving your truck unattended.

You can have confidence that your tonneau cover is securely fastened, protecting your cargo and truck bed from potential damage or theft.

This peace of mind allows you to focus on your journey and enjoy a worry-free experience.

Tips for Maintaining Proper Tonneau Cover Clamp Tightness

Inspect the Clamps Regularly

Regular visual inspection of the tonneau cover clamps is essential. Look for any signs of wear, damage, or loosening.

Check the clamp’s grip on the truck bed and the cover itself. Address any issues promptly to prevent further damage.

Tighten the Clamps Correctly

When tightening the clamps, use a wrench or a suitable tool for a strong grip. Apply steady force while turning the clamp screws clockwise.

Avoid over-tightening, as it may damage the clamps or the truck bed. Strike a balance between firmness and avoiding excessive pressure.

Adjust for Temperature Variations

Temperature fluctuations can affect the tightness of the tonneau cover clamps. In cold weather, the clamps may contract, potentially loosening the grip.

Similarly, the clamps might expand in hot weather, altering their tightness. Regularly monitor the clamp tension and make adjustments as needed.

Secure All Clamps Equally

For tonneau covers with multiple clamps, it’s crucial to distribute the tightness evenly across all the clamps.

Tightening one clamp more than the others can lead to an imbalanced fit, compromising the cover’s effectiveness and potentially causing damage.

Consider Using Anti-Slip Pads or Liners

You can use anti-slip pads or liners to enhance the grip between the tonneau cover clamps and the truck bed.

These accessories can help prevent any potential sliding or shifting of the clamps, ensuring a secure and tight fit.

Clean and Maintain the Clamps

Maintaining clean and debris-free clamps is essential for optimal performance.

Regularly clean the clamps and remove any dirt, dust, or rust that may hinder their functionality.

Lubricating the clamp screws with a suitable lubricant can also facilitate smooth tightening and prevent corrosion.

Monitor the Tonneau Cover’s Fit

Keep an eye on the tonneau cover’s overall fit and alignment. If you notice any sagging, misalignment, or gaps, it may indicate an issue with the clamp tightness.

Make necessary adjustments to ensure a snug fit and maintain the cover’s ability to protect your truck bed.

Can I Use the Same Methods to Determine Tongue Weight Without a Scale to Determine How Tight Clamps Should Be on a Tonneau Cover?

When determining how tight clamps should be on a tonneau cover, utilizing the same methods to determine tongue weight without a scale may not be applicable. Tongue weight pertains to the downward pressure exerted on a hitch ball, while determining clamp tightness requires considering the cover’s secure fitment. Thus, different considerations and techniques are necessary for these distinct purposes.

FAQs

What Happens If The Clamps On A Tonneau Cover Are Too Loose?

If the clamps are too loose, the tonneau cover may flap or shift while driving, potentially causing damage or reducing its effectiveness in protecting the truck bed.

Can The Clamps On A Tonneau Cover Be Too Tight?

If the clamps are excessively tightened, they can strain or deform the tonneau cover, leading to premature wear or tear.

How Can I Ensure The Clamps Are Properly Tightened On My Tonneau Cover?

Start by loosely attaching the clamps, then adjust them gradually while checking for a snug and secure fit. Avoid overtightening to prevent damage.

Is There A Specific Torque Specification For Tightening Tonneau Cover Clamps?

The recommended torque specification may vary depending on the tonneau cover brand and model.

It’s best to consult the manufacturer’s instructions for the precise torque requirements.

Can I Use Tools Like Pliers Or Wrenches To Tighten The Clamps?

Using tools like pliers or wrenches is generally unnecessary and can risk overtightening.

Most tonneau cover clamps can be sufficiently tightened by hand.

Final Words

Secure your tonneau cover with properly tightened clamps. Strike the perfect balance—tight enough to keep it in place during your drive but not overly tight to avoid damaging the cover.

Follow the above step-by-step process to hand-tighten the clamps. Regularly check the tightness to ensure optimal performance and protection for your truck bed.